We will answer your questions and inquiries about TSUBAME-Tripod.

-

Why can't you change the leg angle on a TSUBAME tripod?

-

There are two reasons for this:

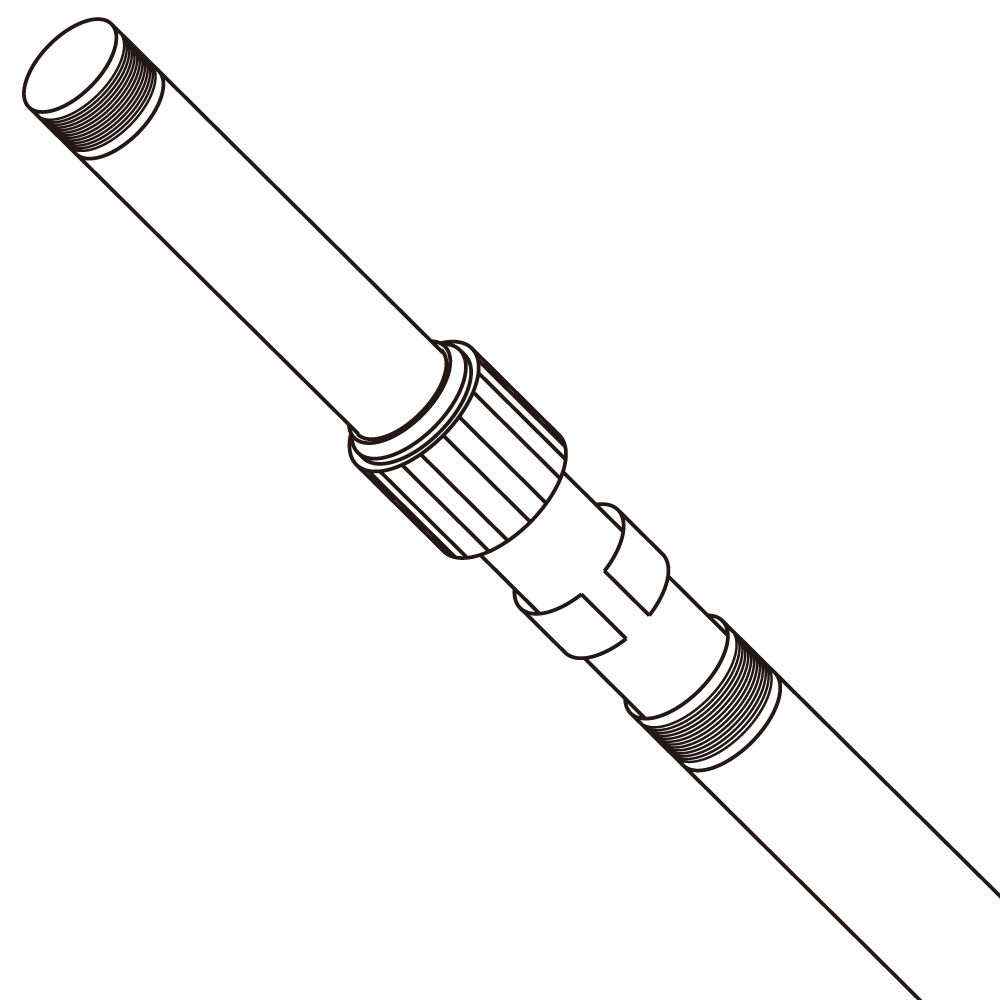

To change the leg angle, the tripod body that holds the three legs must be made of multiple components and made movable. In fact, this tripod body is extremely important as the main body of the tripod, and the "load capacity" of most tripods is determined by the strength of this tripod body. Looking closely at the components, the TSUBAME tripod body is made entirely from a single piece of metal, with only the EV crank gear, stopper knob, and guide pipe attached. Furthermore, the tripod body and the leg adapter at the end of the pipe are designed to have surface contact. All of these designs ensure more than sufficient robustness, durability, and stability, as professional photographers would not want to sacrifice anything.

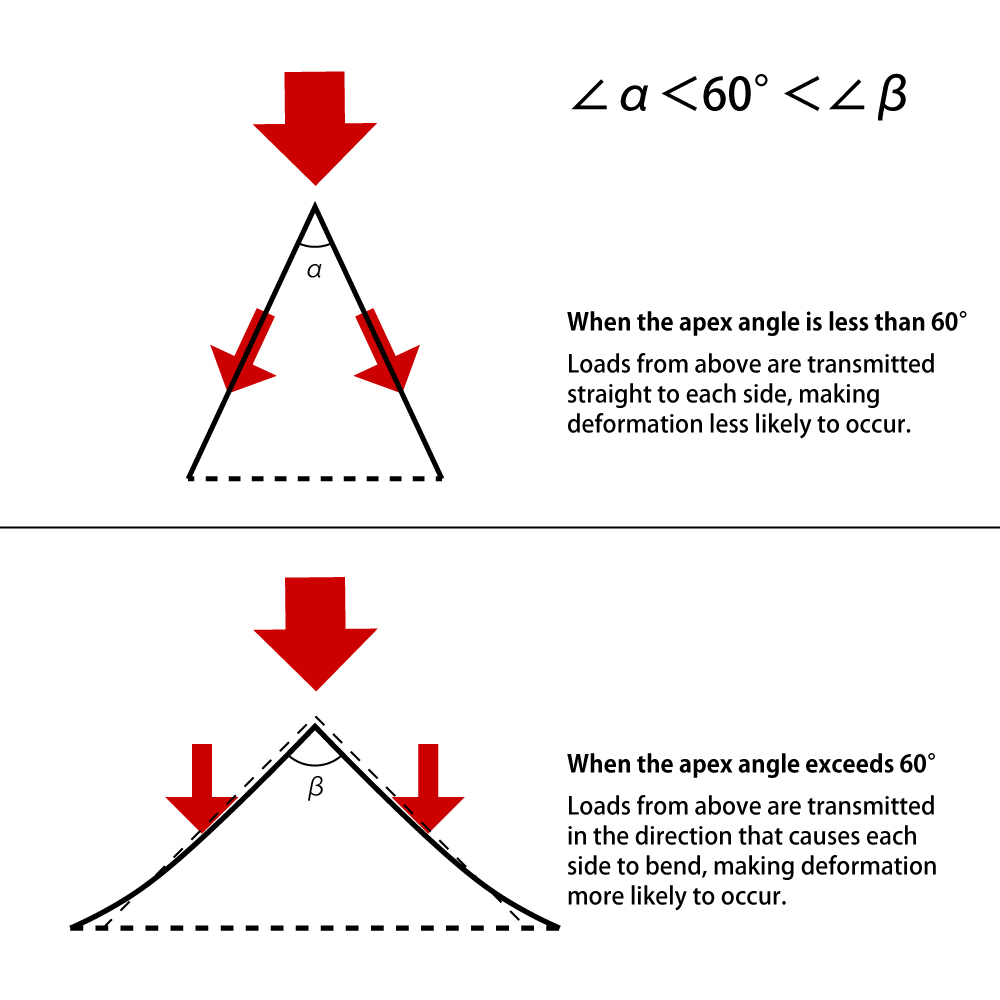

Also, when looking at the tripod from the side, take a look at the triangle formed by the two leg pipes and the ground. On flat ground, it forms an isosceles triangle. However, if the apex angle is less than 60 degrees, the weight of the equipment will be transferred directly to the pipes. If it is greater than 60 degrees, the load will be transferred in a direction that causes the pipes to bend laterally. Being able to spread your legs at an angle of more than 60 degrees does not necessarily mean you can take stable photos.

-

Isn't this a disadvantage for low-angle shooting?

-

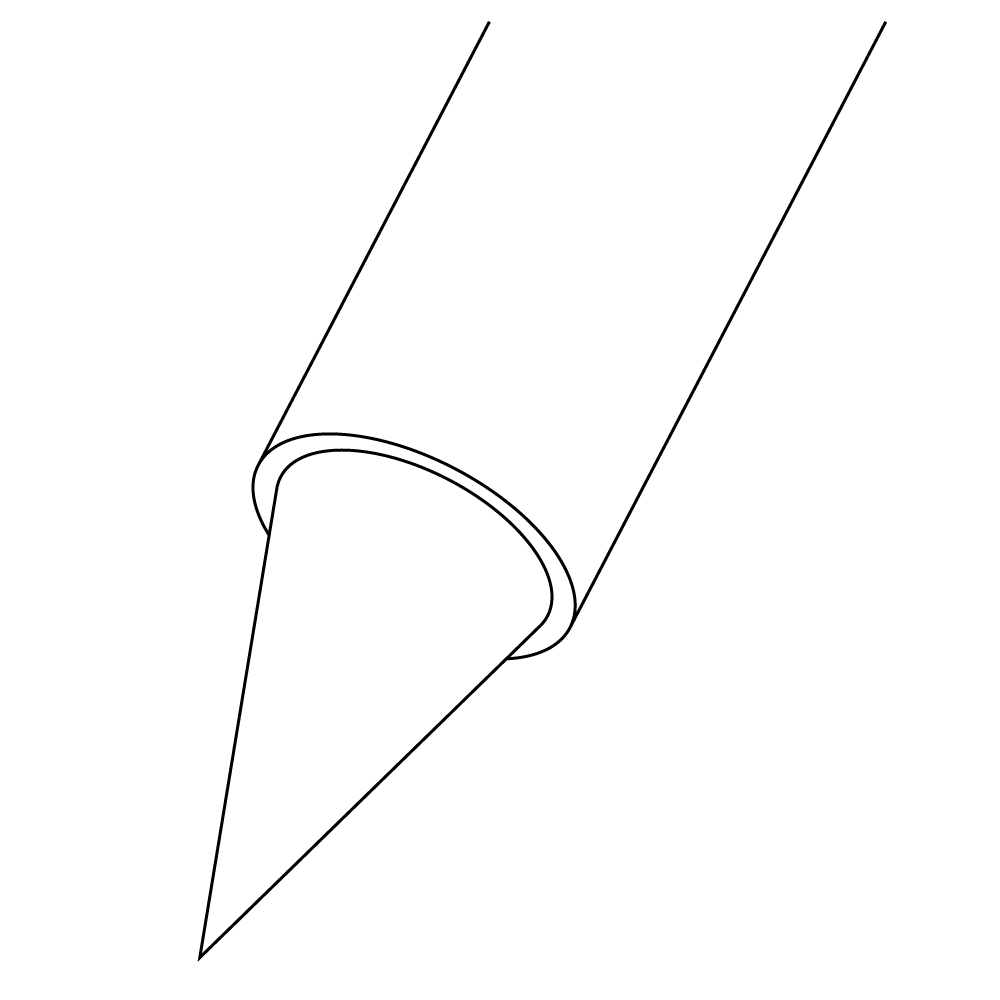

Related to the previous question, when trying to take low-angle shots with a tripod that allows for adjustable leg angles, even with the legs fully extended, you'll still be about 15cm above the ground. When a head is attached to that and the camera body and lens are placed on top of that, it seems that most tripods have a minimum shooting height of at least 25-30cm.

If you pull out the TSUBAME elevator and shoot in reverse, with a tripod with an integrated head, you can shoot from a height of about 13cm, the length of the horizontal pan rod. If you combine a ball head with a KIRK model or a tripod with a detachable head and use an L-bracket, you can lower the camera all the way to the ground without having to turn it sideways or upside down.

Whether you can truly achieve low-angle shots freely depends on whether you can shoot in reverse with the elevator.

-

Isn't it inconvenient when the upper pipe rotates when tightening or loosening the leg pipe?

-

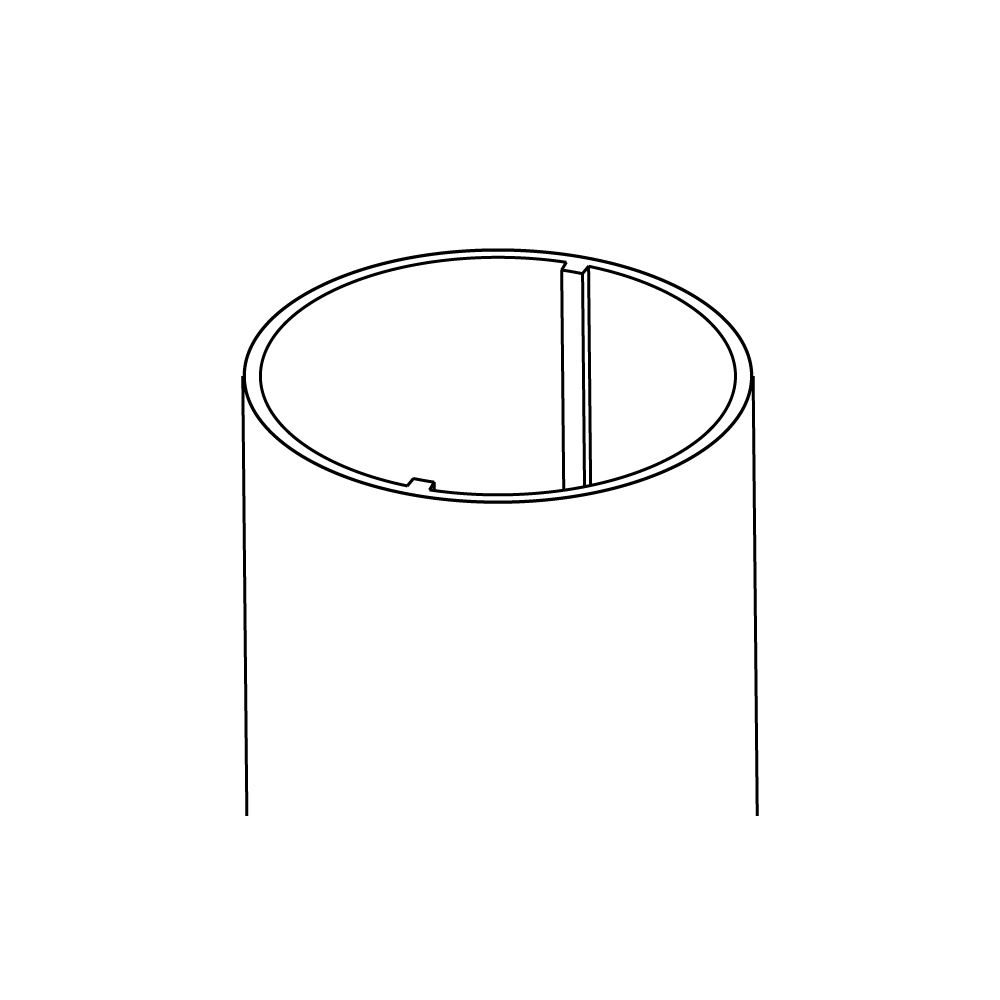

To prevent the leg pipe from rotating with the lock ring, it is necessary to add one (or two) ribs to the inside of the pipe, acting as a spine. While it is not impossible to perform this process on metal pipes, it would be extremely expensive, and we decided that we did not want to reflect that in the product price. Also, the closer the cross-section of the leg pipe is to a perfect circle, the greater its strength will be. If unnecessary processing were to destroy this perfect circle and reduce strength, it would be all for nothing. As long as you get into the habit of gripping the pipe one level above when turning the leg pipe lock ring, we don't think it will be much of a problem.

-

Why are there only rubber tips at the ends of the leg pipes and no spikes available?

-

In fact, we once made a one-of-a-kind item at a customer's request. On a midwinter night in Alaska, on the frigid frozen soil and ice, spikes made of nothing more than sharpened stainless steel rods had no grip whatsoever and actually made you slip, so we found that spikes with rubber tips were far superior. As an improved version, we created spikes with the same carbide tips as ski poles embedded in the tips, and finally created something we were satisfied with, but they were quite expensive. Some people may need them, but for those who just think they might be convenient, it is an unnecessary expense.

Please note that if you use spikes in unfrozen soil, sand, or fresh snow, the leg pipes will easily bend when strong lateral forces are applied, making them impossible to store.

-

I have to use a lot of force to tighten each locking part to stop it.

-

This is probably true for most industrial products, but overtightening all lock rings and lock knobs is strictly prohibited. Tightening the threads where metal pieces interlock will cause rapid wear. If the grease normally applied to the threads runs out or foreign matter gets mixed in, this process will accelerate, eventually overcoming the threads and making it impossible to tighten.

For example, if you pull out the leg pipes and tighten the metal lock ring, and you have to use all your strength to tighten it, it's possible that grease or dirt has accumulated on the plastic internal lock ring. Completely loosen the metal lock ring, remove the internal lock ring, clean it thoroughly with a plastic-safe parts cleaner, wipe each pipe, and then reassemble. This should improve the problem.

Column Lock knobs are also a common problem area. If the tips of the EV post or lock knob are dirty or have grease on them, the EV post will slide down if you don't tighten it properly, and the steel male thread will wear down the aluminum alloy female thread. If this limit is exceeded, the knob will spin freely, requiring repair.

-

Tilt level lock knob shaft is bent.

-

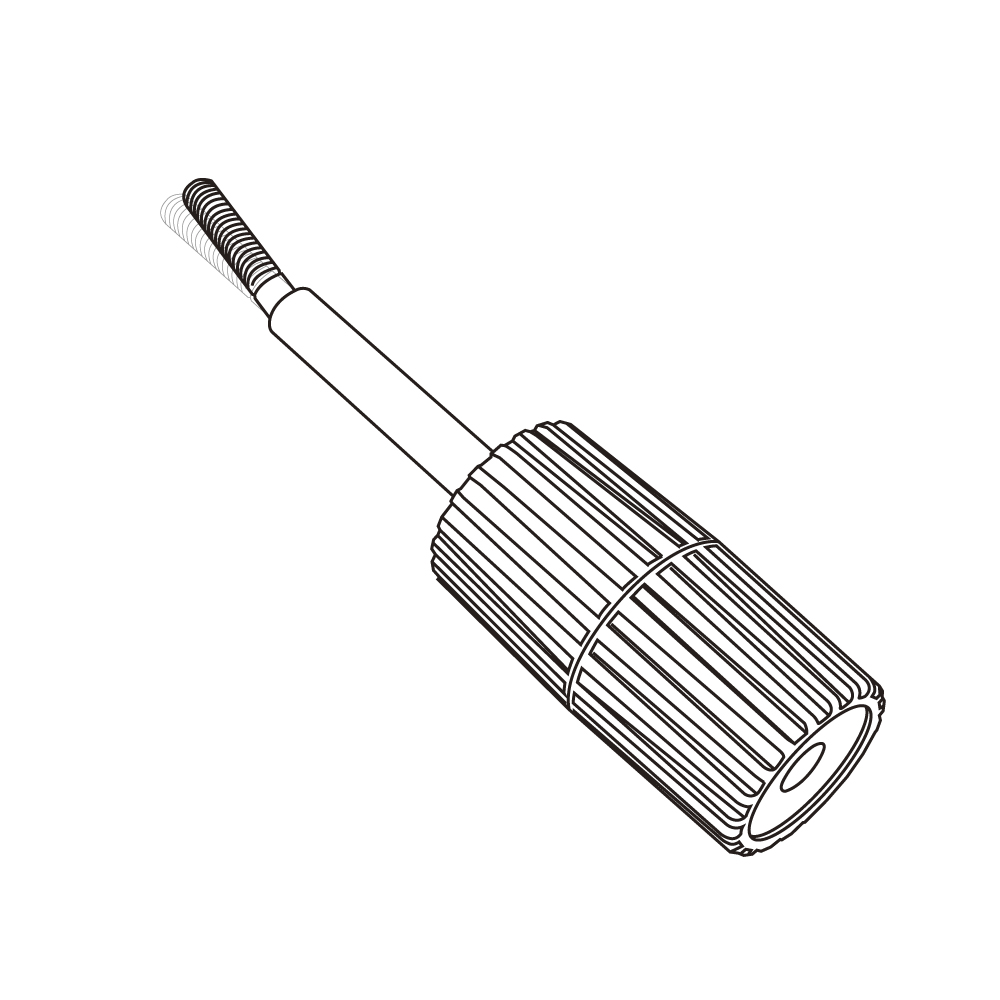

Tilt level lock knob extend in two directions from the 3D head, and a separate EV crank gear handle protrudes from the legs. Of course, this shape was originally designed for ease of use, but it also serves another important purpose. The material was selected to bend and absorb the impact if the tripod were to tip over for any reason. Being unable to continue shooting due to an accident can be fatal for a professional photographer, so the design aims to reduce that probability as much as possible.

If you continue to use the tripod while it's bent, the steel lock knob shaft and the brass internal locking link will no longer be parallel, and the brass side will give way and gradually wear down. Eventually, the pan bar will penetrate the internal locking link and come into direct contact with the connecting pivot or head drum. In this state, there's no longer any holding power or control, so we don't recommend continuing to use it while it's even slightly bent.

However, this does not mean that you can simply bend a bent lock knob shaft back into a straight position. If you forcefully straighten a bent metal piece, it will create tiny cracks inside, and if you continue to tighten and loosen it in that state, the cracks will continue to grow until it suddenly snaps. To prevent this from happening while you are shooting, bend a lock knob shaft and replace it with a new one as soon as possible.